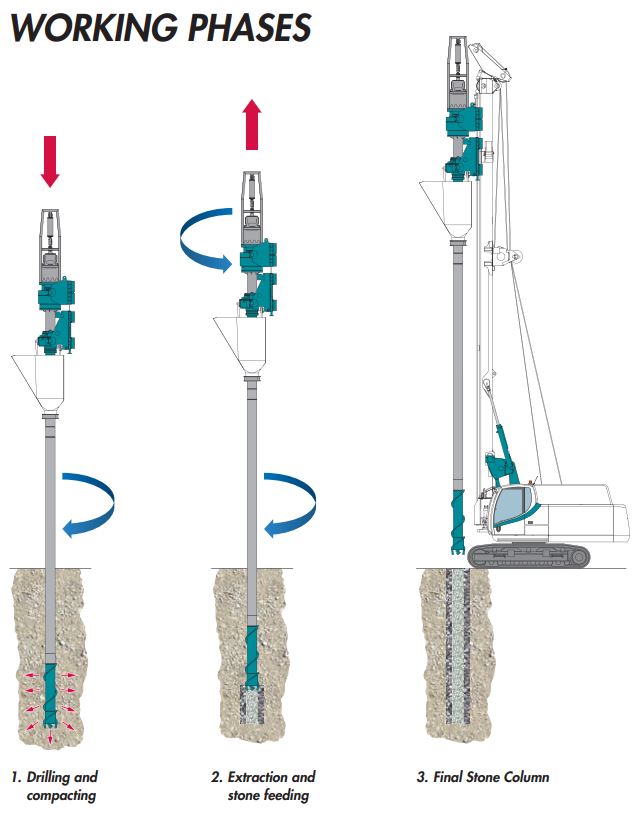

Casagrande spa, working closely with customers using vibratory stone column techniques, has developed a patented drilling application for the installation of stone column piles without the use of a vibroflott or vibrohammer.

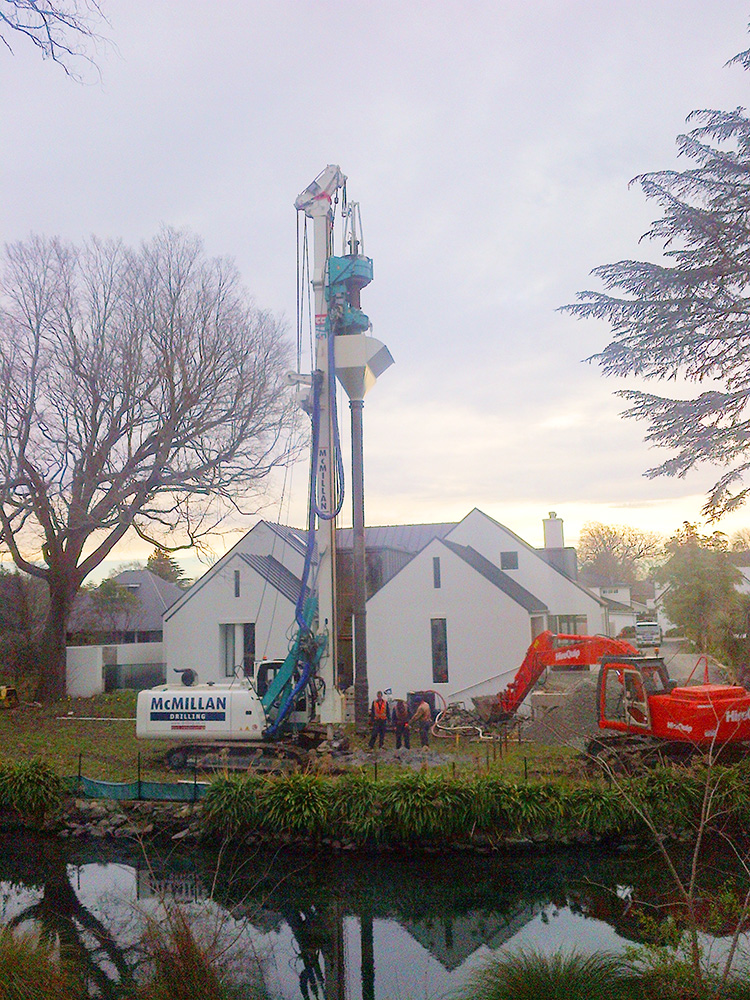

The new ground improvement method is vibration free, so it can be used immediately next to sensitive sites or neighbouring buildings

- Benefits of this piling application are:

- Less power required as no need to supply a high frequency vibrator.

- Fuel savings due to smaller power consumption in total.

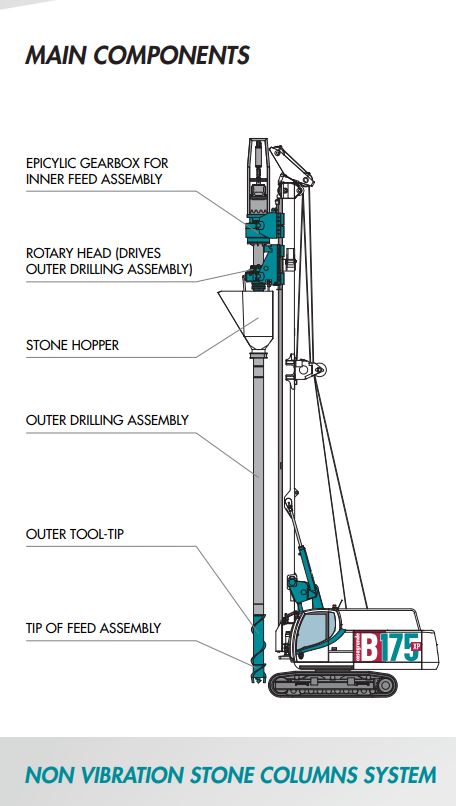

- Only two plant items required, one to drill the other to load the stone for bottom feed stone column hopper.

- Fast to set up.

- No high-pressure water or air injection required therefore less mess.

- Bottom feed – can be used in collapsing soils.

- Binder can be introduced to provide rigid inclusions in the soil – no expensive concrete delivery trucks or pumps required.

- Does not create liquefaction state of soil with related possible machine instability due to vibration.

- No high wear or maintenance due to high frequency vibrating parts.

- Proven technique in several different soil types.

- Recognised by international geotechnical engineering design companies, due to close collaboration within ground engineering customers markets.

No introduction of high pressure water or air is required to expel the stone from the feed tube, the system is relatively mess free. Sites immediately adjacent to sensitive environments can be completed with the full knowledge that no high frequency vibrations or impact noise have affected the ground stability.

The tooling is a hybrid drilling assembly, this allows tool penetration through hard layers and removes the requirement for predrilling, that is often required for vibratory piling techniques.

The drilling method builds complete columns always, so there is no-void space introduction which may allow column contamination, at any time. Unlike methods where a plunging motion is used for stone compaction.

Fuel and Cost Savings: on traditional stone column systems. As the drilling application does not require any additional power packs, only one rig to perform the job.

Casagrande designed the application to be attached to a conventional rotary piling rig, thus a truly multi-purpose machine that can be converted back to other techniques is possible.