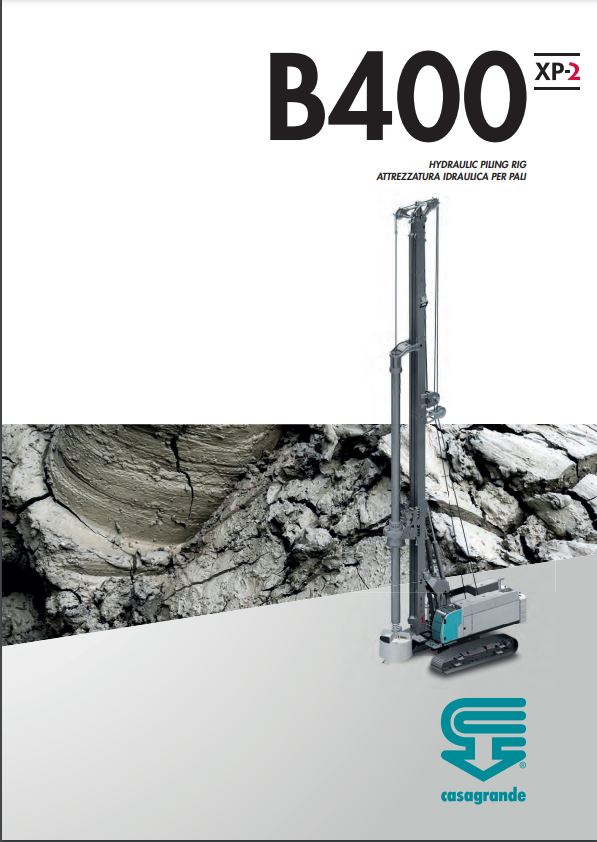

B400 XP-2

The Casagrande B400 XP-2 is a multifunctional hydraulic piling rig for foundation construction by drilling large and small boreholes in rotary piling.-

450 kW

450 kWEngine Power

-

690 kN

690 kNExtraction Force

-

50 RPM

50 RPMRotary Head Speed

-

2700 MM

2700 MMRotary Diameter

-

99 M

99 MRotary Depth

-

690 kN

690 kNCrowd Force

-

467 kNm

467 kNmRotary Head Torque

-

128 T

128 TOperating Weight

- ABOUT

- TECHNICAL DATA

- OPTIONS

INTRODUCTION

Casagrande’s new series of XP-2 hydraulic piling rigs are designed and built using the latest state-of the-art techniques. A range of machines engineered to satisfy the needs of the most demanding contractor with emphasis on performance, reliability and economy.

The Casagrande B400 XP-2 is a multifunction machine designed to drill boreholes, to insert and extract casings, to power a casing oscillator, for piling by the continuous flight auger method and ready for conversion in diaphragm wall equipment.

Due to the high torque of the rotary head of up to 467 kNm, the HD kelly bars and a powerful winch, the B400 XP-2 can rapidly drill deep and large piles in hard soils. The crowd winch will drive casings deep into the ground with extreme accuracy having a line pull of 600 kN and rotary head stroke of 21 m

“Keep the operator happy in a comfortable working environment” is our formula for added productivity. The B400 XP-2 is designed to satisfy the severe European Union standards on safety and is manufactured to comply with the ISO 9001 requirements on quality.

PERFORMANCE AND PRODUCTIVITY

SAFETY & TECHNOLOGY

FULL LOAD SENSING TECHNOLOGY

| FEATURE | UK |

|---|---|

| Max depth | 99 m |

| Max diameter | 3500 mm |

| Engine power | 450 kW |

| Width of crawler | 3500÷5000 mm |

| Shoes width | 1000 mm |

| MAIN WINCH | |

| Line pull | 375 kN |

| AUXILIARY WINCH | |

| Line pull | 150 kN |

| CROWD – RAM | |

| Extraction force | 400 kN |

| Crowd force | 250 kN |

| Stroke | 7000 mm |

| CROWD – WINCH | |

| Extraction force | 690 kN |

| Crowd force | 690 kN |

| Stroke | 21000 mm |

| ROTARY HEAD | |

| Torque | 467 kNm |

| Drilling speed | 50 rpm |

| WEIGHT | |

| Weight in working condition | 124 t |

STANDARD EQUIPMENT

- SPM control system – Smart Power Management

- 12″ touch screen display for visualization and drilling parameter settings

- Mast lifting and lowering aid

- Drilling depth measurement and automatic mast verticality control

- Automatic idling mode with engine start/stop for fuel saving

- Rotary shaking system for tool discharge

- Hook on auxiliary line

- Protective roof guard (FOPS compliant)

- Air condition system

- Cab side catwalk

- Electric refuelling pump

BASIC MACHINE

- Undercarriage with 800 mm wide track shoes

- Lateral catwalks and handrails

- Water pre-heating system for starting engine at low temperatures

- Automatic centralized greasing system

- Cable remote control for tracking

- Video unit with two cameras and one 7″ monitor to control winches and the rear of the machine

- Automatic self-alignment on drilling

- Casagrande FleetMaster remote rig control and monitoring via internet

- Transport kit according to required transport configuration

ROTARY PILING EQUIPMENT

- Rotary head extension to increase the drilling diameter

- Low headroom arrangement

- H47 rotary head

- Cardanic joint for rotary head

- Main controlled winch 415 kN nominal line pull

- Main free fall winch 250 kN nominal line pull

- Auxiliary free fall winch 140 kN nominal line pull

- Load cell on auxiliary winch for line pull monitoring

- Pull control and overload protection for pull-down winch

- Hydraulic mast folding for transport

- Hydraulic jib folding for transport

- Arrangement for casing oscillator

- Casing oscillator GCL 1500. SE

CFA EQUIPMENT

- Measurement and visualization of extraction force.

- Rotating CFA cleaner hydraulically operated

- Star CFA cleaner

- CFA lower guide with hydraulic opening

- Crowd winches for CFA. Max crowd force 2 x 55

- Hydraulic vibrator for cages

- Instrument for measuring, displaying and recording of drilling parameters. The instrument is complete with software for processing the data on a PC

- Instrument for continuous extraction of CFA