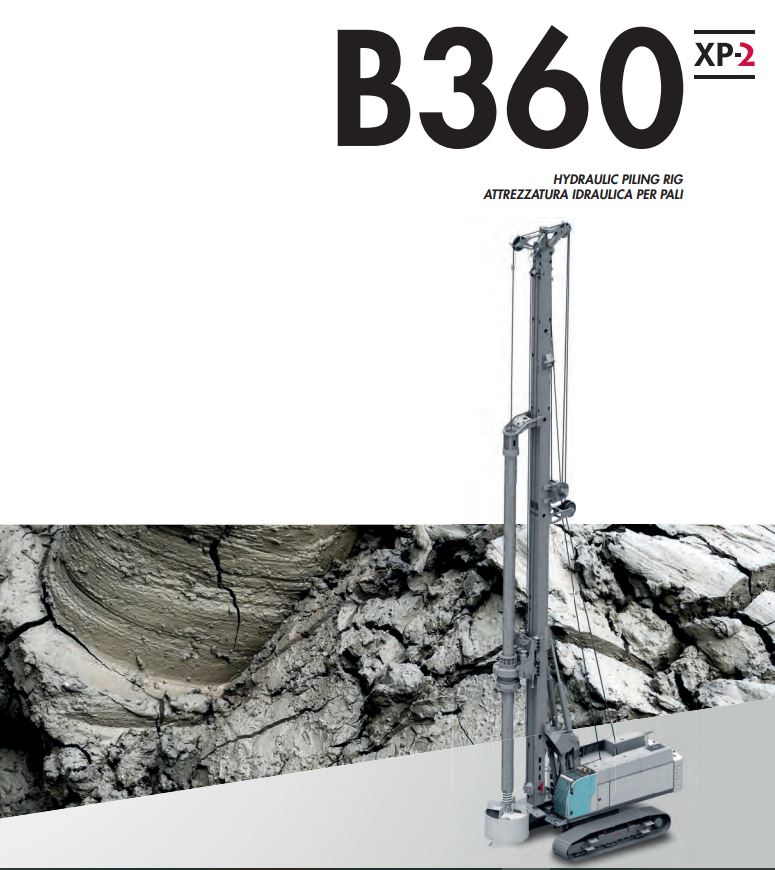

B360 XP-2

The Casagrande B360 XP-2 is a multifunctional hydraulic piling rig for foundation construction by drilling large and small boreholes in rotary piling.-

400 kW

400 kWEngine Power

-

690 kN

690 kNExtraction Force

-

2700 MM

2700 MMRotary Diameter

-

101 M

101 MRotary Depth

-

690 kN

690 kNCrowd Force

-

400 kNm

400 kNmRotary Head Torque

-

122 T

122 TOperating Weight

- ABOUT

- TECHNICAL DATA

- OPTIONS

INTRODUCTION

The Casagrande B360 XP-2 is a machine dedicated to give the specialist contractor an equipment to perform large diameter rotary piling. It is the result of research and innovation based on over 50 years of experience and success of the company in the field of foundations and geotechnical engineering.

Thanks to the high torque of the rotary head up to 400 kNm, to the HD kelly bars and a powerful winch, the B360 XP-2 is able to drill quickly deep and large piles in hard soils. The crowd winch with a line pull of 600 kN and the stroke of the rotary head of 21 m.

The SPM (Smart Power Management) allows an intelligent engine power management to improve performances and productivity of machinery. The XP technology monitors the instantaneous power flows and allocates the full available power to the job duties. The results is an increasing of the machine efficiency.

The design guidelines have taken particular care in the welfare of the operator and its high level of professional performance. In particular, best results were obtained in terms of ergonomics, both in the cabin and outside of the machine, and with regards to noise reduction.

PERFORMANCE AND PRODUCTIVITY

SAFETY & TECHNOLOGY

FULL LOAD SENSING TECHNOLOGY

| FEATURE | UK |

|---|---|

| Max depth | 99 m |

| Max diameter | 3500 mm |

| Engine power | 400 kW |

| Width of crawler | 3000÷5000 mm |

| Shoes width | 1000 mm |

| MAIN WINCH | |

| Line pull | 375 kN |

| AUXILIARY WINCH | |

| Line pull | 150 kN |

| CROWD – RAM | |

| Extraction force | 400 kN |

| Crowd force | 250 kN |

| Stroke | 7000 mm |

| CROWD – WINCH | |

| Extraction force | 690 kN |

| Crowd force | 690 kN |

| Stroke | 21000 mm |

| ROTARY HEAD | |

| Torque | 400 kNm |

| Drilling speed | 25 rpm |

| WEIGHT | |

| Weight in working condition | 123 t |

STANDARD EQUIPMENT

- SPM control system – Smart Power Management

- 12″ touch screen display for visualization and drilling parameter settings

- Mast lifting and lowering aid

- Drilling depth measurement and automatic mast verticality control

- Automatic idling mode with engine start/stop for fuel saving

- Smart lowering and overload protection for main winch

- Rotary shaking system for tool discharge

- Hook on auxiliary line

- Protective roof guard (FOPS compliant)

- Air condition system

- Cab side catwalk

- Electric refueling pump

- Hydraulic self lifting counterweight

BASIC MACHINE

- Undercarriage with 800 mm wide track shoes

- Additional counterweight 4000 kg, according to the arrangement

- Cab front board

- Lateral catwalks and handrails

- Water pre-heating system for starting engine at low temperatures

- Automatic centralized greasing system

- Cable remote control for tracking

- Video unit with two cameras and one 7″ monitor to control winches and the rear of the machine

- Automatic self-alignment on drilling

- Casagrande FleetMaster remote rig control and monitoring via internet

- Hydraulic self lifting counterweight

- Transport kit according to required transport configuration

ROTARY PILING EQUIPMENT

- Mast extension for extended mast version

- Low headroom arrangement

- Cardanic joint for rotary head

- Main controlled winch 360 kN nominal line pull

- Main free fall winch 250 kN nominal line pull

- Auxiliary free fall winch 140 kN nominal line pull

- Load cell on auxiliary winch for line pull monitoring

- Pull control and overload protection for pull-down winch

- Hydraulic mast folding for transport

- Hydraulic jib folding for transport

- Arrangement for casing oscillator

- Casing oscillator GCL 1500 SE

CFA EQUIPMENT

- Measurement and visualization of extraction force

- Rotating CFA cleaner hydraulically operated

- Star CFA cleaner

- CFA lower guide with hydraulic opening

- Crowd winches for CFA. Max crowd force 2 x 55

- Hydraulic vibrator for cages

- CFA feed control

- Instrument for measuring, displaying and recording of drilling parameters. The instrument is complete with software for processing the data on a PC

- Instrument for continuous extraction of CFA