DUPLEX Drilling System

Sysbohr Duplex Overburden Drilling System88.9mm - 323.9mm (3 1/2" - 12 3/4")

- About

- Specifications

Duplex Overburden Drilling System from Sysbohr

A method of drilling through overburden with the aid of an outer casing to support the borehole wall is the so-called duplex drilling process.

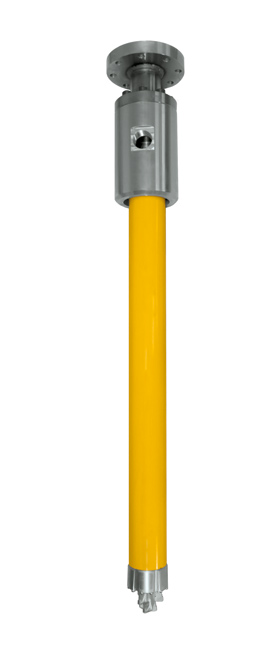

The system depicted here is drilled simultaneously with outer casings and inner rods and driven by a rotary head unit.

The flushing for the discharge of the cuttings is directed through the centre of the inner drill string, conveyed to the toe of the borehole and carried back up the drill string, in the annular space between the inner surface of the outer casing, and the outer surface of the inner rod, above ground and expelled from the system.

Depending on the ground formations, casing bits and rotary drill bits are utilised and / or a DTH hammer as well. If the use of flushing media such as air or water are prohibited during drilling due to structural or environmental concerns, then an auger drill rod may be used to discharge the drill cuttings to surface, in a similar fashion to an Archimedean screw. In this case, the outer casings and inner auger drill rods are drilled successively.

First the outer casing string and then the auger string are drilled in succession or vice versa.

There is a complete system from D 88.9 mm (3-1/2”) to D 323.9 mm (12-3/4”) available with a wide assortment of external casings and inner rod combinations, as well as a plethora of ground specific drill bit designs available.

1 Shank adapter to suit hydraulic drifter brand and model

2 Flushing ring holder tailor-made to integrate seamlessly with brand and model of hydraulic drifter as well as drill mast characteristics

3 Flushing ring lip seals

4 Flushing ring with a suitable / incorporated hose connection

5 Flushing shaft to suit shank adapter, ejection bell and balancing rod

6 Ejection bell to suit flushing shaft and outer casings

7 Balancing rod to suit flushing shaft and inner drill rods

8 Roto-percussive casings (outer drill string) – in lengths of 500 mm (approx. 1-5/8’) to 6000 mm (approx. 20’)

9 Roto-percussive drill rods (inner drill string) – in lengths of 500 mm (approx. 1-5/8’) to 6000 mm (approx. 20’)

10 Casing bit

11 Percussion bit