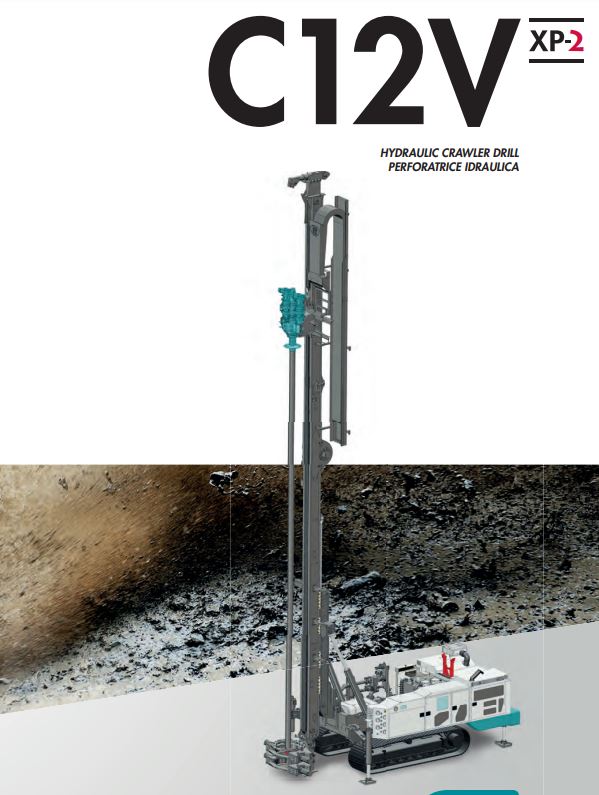

C12V XP-2

The Casagrande C12V XP-2 drill rig is designed for larger projects in the field of foundation and is suited for constructing anchors, micropiles, CFA piles and jet-grouting.-

194 kW

194 kWEngine Power

-

150 kN

150 kNExtraction Force

-

29 T

29 TOperating Weight

- about

- technical

INTRODUCTION

The C12V XP-2 is the new Casagrande drill rig designed and manufactured to tackle the larger projects in the field of foundation and is suited for constructing anchors, micropiles, CFA piles and jet-grouting.

Due to the slew ring that connect the rig’s upper structure to the undercarriage, the C12V XP-2 is a machine highly manoeuvrable and with easy setting up easy even on the most confined sites.

The SPM – Smart Power Management – and the full load sensing hydraulic system allow an intelligent engine power management to improve performance of the machinery and reduce fuel consumption. Available in hydraulic and full radio-controlled version, the new C12V XP-2 is designed thinking of the operator.

PERFORMANCE AND PRODUCTIVITY

The Smart Power Management (SPM) is an intelligent engine power management system that improves performances and productivity of the machinery. The SPM system monitors the momentary power flows and immediately allocates the available power to the required jobs, so the main function has the maximum power available.

SAFETY & TECHNOLOGY

The C12 XP-2 has a very low sound emission level due to the sound-absorbing materials used and oil heat exchangers, designed for reducing the overall noise level. The layout of the machine and the wide openings of the canopy offer comfortable and easy access for inspection and maintenance. The machine conforms to the last international standards to guarantee maximum safety.

FULL LOAD SENSING TECHNOLOGY

The XP-2 hydraulic power system uses the Full Load Sensing (FLS) technology. Unlike the common hydraulic managing systems, the FLS pressurizes only the required amount of oil needed thanks to the feedback between pumps and distributors. Thus allowing the management of the power demands and reduces dissipation, achieving up to 25% fuel saving (calculated on the basis of a theoretical working cycle).

FLEXIBILITY

The XP-2 control system offers the following advantages for the operator:

- monitoring of all working function,

- diagnostic of the working systems to ensure the constant monitoring of the status of sensors and components,

- easy conversion in any drilling arrangement,

- friendly customization of working functions e.g. mappings of torque and speed for EP rotary head,

- remote rigs assistance,

- diagnostic, monitoring of working parameters.

| Technical Data | |

|---|---|

| Mast | |

| Stroke of rotary head | 10060 ÷ 13000 mm (33 ÷ 42.7 ft) |

| Clamps | |

| Diameters | 178 ÷ 610 mm (7 ÷ 24 in) |

| Rotary head | |

| Torque | 55000 Nm (40,565 lbf/ft) |

| Max. drilling speed | 50 rpm |

| Weight | |

| Weight in working condition | 29500 kg (65,036 lbs) |

Optional Equipment

- Other rotary heads available

- Drifter type T40 – T50 (Back Device)

- Rotopercussion unit HB50A – HB60A

- Auxiliary winch with rope – Max line pull 2000 kg – 3000 kg

- Cathead for auxiliary winch

- Self-pivot pulley Cathead with self-pivoting pulley for auxiliary winch

- Telescopic and swinging cat head

- Auxiliary crane

- Jet grouting system

- Super jet grouting arrangement

- Hydraulic chuck type P114 – P200 for jet grouting rods

- Flushing pump – Water pump

- GAMMA 62 (60 l/min max – 50 bar max)

- GAMMA 202 (200 l/min max – 60 bar max)

- Pump CC30/20S

- Foam: (30 l/min max – 50 bar max)

- High pressure: (30 l/min max – 200 bar max)

- Mud pump:

- NG530 L (215 l/min – 24 bar)

- NG600 L (310 l/min – 24 bar)

- NG800 L (480 l/min – 20 bar)

- NG1200 L (960 l/min – 14 bar)

- Lubricator for down-the-hole hammer 8,5 l – 20 l

- Manual centralized greasing system

- Safeguards according to EN 16228

- Casagrande FleetMaster remote rig control and monitoring via internet