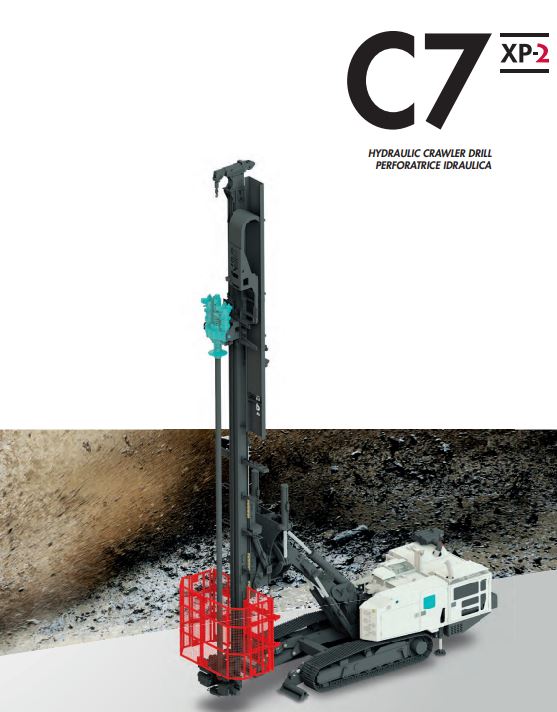

C7 XP-2

The C7 XP-2 drilling rig, with the new joints system providing total flexibility to reach the most extreme drilling positions. For larger foundation projects, anchor construction, micropiles and jet-grouting.-

186 kW

186 kWEngine Power

-

86.5 kN

86.5 kNExtraction Force

-

22 T

22 TOperating Weight

Product Catalogue

Casagrande C7XP-2 Brochure

- about

- technical

INTRODUCTION

The C7 XP-2 is the new Casagrande drill rig designed and manufactured to tackle the larger projects in the field of foundation and is suited for constructing anchors and micropiles and is particularly suited to jet-grouting. A machine engineered for the most demanding conditions with particular emphasis on performance efficiency, reliability and economy. The C7 XP-2 is a rapid machine to operate, easy to use (user-friendly) with total flexibility due to the new joints system which allows the most extreme drilling position to be achieved.

PERFORMANCE AND PRODUCTIVITY

| Technical Data | |

|---|---|

| Mast | |

| Stroke of rotary head | 8000 ÷ 10000 mm |

| Clamps | |

| Diameters | 101 ÷ 508 mm |

| Rotary head | |

| Torque | 7000 Nm |

| Max. drilling speed | 50 rpm |

| Weight | |

| Weight in working condition | 21000 kg |

Optional equipment

- Other rotary heads available

- Drifter T40 (Back Device)

- Rotopercussion unit HB45A, HB50A

- A2 auxiliary winch with rope Max line pull 2000 kg

- Cathead for auxiliary winch A2

- Self-pivot pulley Cathead with self-pivoting pulley for auxiliary winch A2

- Auxiliary crane

- Jet grouting system

- Super jet grouting arrangement

- Hydraulic chuck type P114 – P200 for jet grouting rods

- Flushing pump-Water pump GAMMA 202 (200 l/min max – 60 bar max)

- Foam pump G40 (30 l/min max – 50 bar max)

- Lubricator for down-the-hole hammer 8,5 l | 20 l

- Mud pump NG 530 L / PH 15 (160 – 55) 170 l/min | 24 bar

- High pressure pump cleaner

- Safeguards according to EN 16228

- Casagrande Live Dashboard remote rig control and monitoring via internet