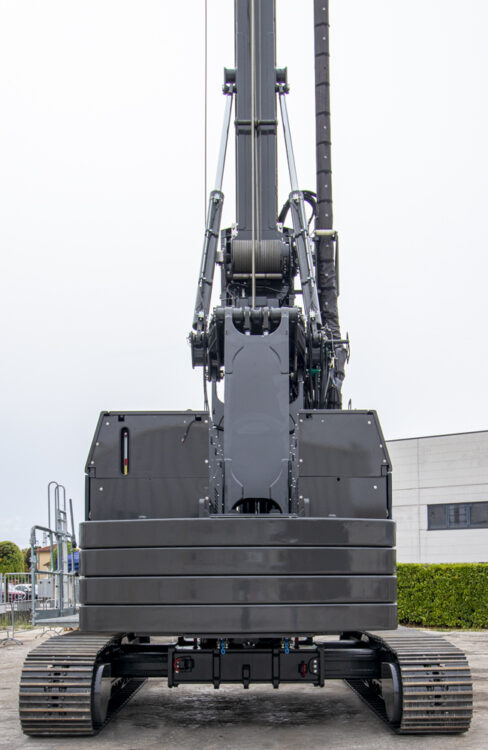

B240 XP-2

The Casagrande B240 XP-2 is a multifunctional hydraulic piling rig for foundation construction by drilling large and small boreholes in rotary piling.-

283 kW

283 kWEngine Power

-

263 KNm

263 KNmTorque

-

420 kN

420 kNExtraction Force

-

700 MM

700 MMShoes Width

-

250 kN

250 kNMain Line Pull

-

87 kN

87 kNAux Line Pull

-

420 kN

420 kNCrowd Force

-

19000 MM

19000 MMStroke Force

-

263 kNm

263 kNmRotary Head Torque

-

38 RPM

38 RPMDrilling Speed

-

69 T

69 TOperating Weight

-

3000-4500 MM

3000-4500 MMWidth Of Crawer

- ABOUT

- TECHINCAL DATA

- OPTIONS

INTRODUCTION

The Casagrande B240 XP-2 is a multifunctional hydraulic piling rig for foundation construction by drilling boreholes in rotary piling, Large Diameter Piling (LDP), to insert and extract casings, to power a casing oscillator, for piling by the continuous flight auger method (CFA Rapid), displacement piles (DP) and soil mixing.

Designed and built using the latest state of the of art technology. A machine engineered for the most demanding conditions with particular emphasis on performance efficiency, reliability and economy.

“Keep the operator happy in a comfortable working environment” is our formula for added productivity.

The B240 XP-2 is designed to satisfy the European Union standards on safety and is manufactured to comply with the ISO 9001 requirements on quality.

| FEATURE | EU |

|---|---|

| Max depth | 78 m |

| Max diameter | 1900 mm |

| Engine power | 283 kW |

| Width of crawler | 3000 ÷ 4500 mm |

| Shoes width | 700 mm |

| MAIN WINCH | |

| Line pull | 250 kN |

| AUXILIARY WINCH | |

| Line pull | 87 kN |

| CROWD – WINCH | |

| Extraction force | 420 kN |

| Crowd force | 420 kN |

| Stroke | 19000 mm |

| ROTARY HEAD | |

| Torque | 263 kNm |

| Drilling speed | 38 rpm |

| WEIGHT | |

| Weight in working condition | 69 t |

STANDARD EQUIPMENT

- SPM control system – Smart Power Management

- 12” touch screen display for visualization and setting of drilling parameters

- Mast lifting and lowering aid

- Drilling depth measurement and automatic mast verticality control

- Automatic idling mode with engine start/stop for fuel saving

- Rotary shaking system for tool discharge

- Hook on auxiliary line

- Protective roof guard (FOPS compliant)

- Air condition system

- Cab front and side catwalk

- Electric refuelling pump

BASIC MACHINE

- Lateral catwalks and handrails

- Railings on upper structure

- Water pre-heating system for starting engine at low temperatures

- Automatic centralized greasing system

- Radio remote control for rigging, derigging, tracking and positioning

- Video unit with two cameras and one 7″ monitor to control winches and the rear of the machine

- Camera for panoramic view of the area around the machine

- Automatic self-alignment on drilling axis

- Casagrande FleetMaster remote rig control and monitoring via internet

- Transport kit according to required transport configuration

ROTARY PILING EQUIPMENT

- Kelly bars diameter 406 mm

- Drilling axis extension to increase the drilling diameter

- Mast extensions for extended mast version

- Cardanic joint for rotary head

- Smart lowering and overload protection for main winch

- Load cell on auxiliary winch for line pull monitoring

- Pull control and overload protection for pull-down winch

- Hydraulic mast folding for transport

- Hydraulic jib folding for transport

- Arrangement for casing oscillator

- Casing oscillator GCL 1500

CFA EQUIPMENT

- Measurement and visualization of extraction force

- Rotating CFA cleaner hydraulically operated

- Star CFA cleaner

- CFA lower guide with hydraulic opening

- Hydraulic vibrator for cages

- CFA feed control

- Instrument for measuring, displaying and recording of drilling parameters. Complete with software for processing the data on a PC

- Instrument for continuous extraction of CFA