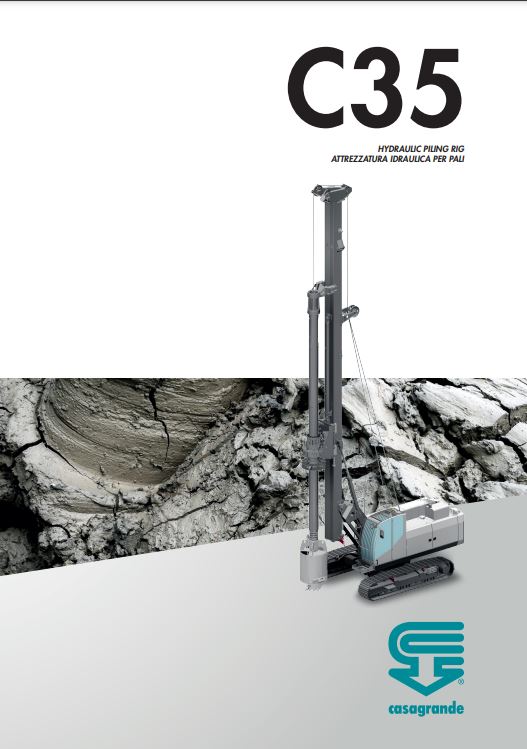

C35

The Casagrande C35 is a multifunctional classic series of hydraulic piling rig for foundation construction by drilling large and small boreholes in rotary piling.-

172 kW

172 kWEngine Power

-

135 KNm

135 KNmTorque

-

190 kN

190 kNCrowd Force

-

39.7 T

39.7 TOperating Weight

- About

- Technical Data

- Optional Equipment

Casagrande’s new series of Classic hydraulic piling rigs are designed to give the contractor efficiency with an emphasis on performance, reliability and economy.

The Casagrande C35 Classic Rig, designed from the tradition to give the specialist contractors an equipment performing foundation techniques in the geotechnical engineering for bored piles and continuous flight auger. Designed to satisfy the European Union standards on safety and is manufactured to comply with the ISO 9001 requirements on quality.

Comfortable cabin and simplified interface keeps the operator efficient and ready for high productivity.

The hydraulic circuit and the controls of the machine are based on traditional electro-hydraulic logic elements in order to be as easy as possible.

PERFORMANCE AND PRODUCTIVITY

The Smart Power Management (SPM) is an engine power management system that improves performances and productivity of the machinery. SPM monitors the power flows drawn from the engine and allocates the maximum available power to the required function.

COMFORT & TECHNOLOGY

The operator cabin is ergonomically designed for user comfort and soundproofing. Smart oil heat exchangers reduce fuel consumption and the overall noise level of the cooling system.

SAFETY AND MAINTENANCE

Hydraulic lifting canopy over the engine for easy access during inspections and maintenance. Optional stairs, platforms and railings provide safe accessibility to every point. Also, optional cameras and display for full visibility of the working area.

ENVIRONMENT AWARENESS

Rigs are powered by the latest generation Stage V diesel engine with reduced exhaust emissions and use of low sulfuric content fuels. Further reduction of CO2 emissions is achievable by using HVO plant-based fuels. Bio-oils of high efficiency and performance are available.

C35 Piling Rig |

|

|---|---|

| Max depth | 50 m |

| Max diameter | 1500 mm |

| Max depth C.F.A. | 13.6 m |

| Max diameter C.F.A. | 800 mm |

| Engine power | 172 kW |

| Width of crawler | 2500÷3700 mm |

| Shoes width | 600 mm |

WINCHES |

|

| MAIN WINCH | |

| Line pull | 165 kN |

| AUXILIARY WINCH | |

| Line pull | 73 kN |

| CROWD – RAM | |

| Extraction force | 205 kN |

| Crowd force | 190 kN |

| Stroke | 3800 mm |

| CROWD – WINCH | |

| Extraction force | 290 kN |

| Crowd force | 290 kN |

| Stroke | 14000 mm |

ROTARY HEAD |

|

| Torque | 135 kNm |

| Drilling speed | 30 rpm |

WEIGHT |

|

| Weight in working condition | 39700 Kg |

STANDARD EQUIPMENT

- 7” screen display for visualization and setting of drilling parameters

- Drilling depth measurement and automatic mast verticality controlled

- Protective roof guard (FOPS compliant)

- Air condition system

- Cab side catwalk

- Electric refuelling pump

BASIC MACHINE

-

- Lateral catwalks and handrails

- Cab front board

- Water pre-heating system for starting engine at low temperatures

- Automatic centralized greasing system

- Video unit with two cameras and one 7” monitor to control winches and the rear of the machine

- Casagrande FleetMaster remote rig control and monitoring via internet

- Transport kit according to required transport confi guration

ROTARY PILING EQUIPMENT

-

- Cardanic joint for rotary head

- Hook on auxiliary line

CFA EQUIPMENT

- Rotating CFA cleaner hydraulically operated

- Star CFA cleaner

- CFA lower guide with hydraulic opening

- Crowd winches for CFA. Max crowd force 2×29 kN

- Hydraulic vibrator for cages

- Instrument for measuring, displaying and recording of drilling parameters.

- Complete with software for processing datas on a PC

- Instrument for continuous extraction of CFA

KRC EQUIPMENT

- Auxiliary controlled winch 70 kN nominal line pull and jib

- Kelly bars and grab for excavation of min 400 mm thickness panels