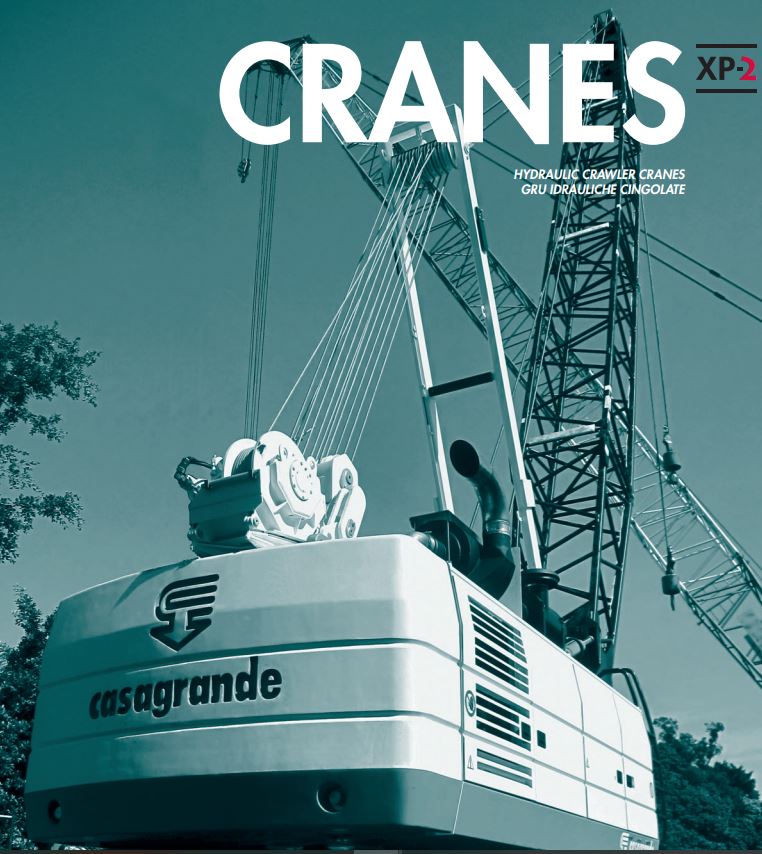

C300XP-2

The C300Xp-2 Crawler Crane: heavy duty winches for controlled or free fall operation, drive casing oscillators, rotary drills, vibrators & diaphragm walls grab.-

186 kW

186 kWEngine Power

-

165 kN

165 kNMain WInch Max Load

-

20.6 M

20.6 MMax Lifting Radius

-

21 M

21 MMax Boom Length

-

2500/3700 MM

2500/3700 MMTrack Width Retracted/Extracted

-

4510 MM

4510 MMTrack Length

-

600 MM

600 MMTrack Pad Width

-

73 kN

73 kNAuxiliary Winch Max Load

-

165 kN

165 kNMain (Freefall) Winch Max Load

-

41

41Auxiliary (Freefall) Winch Max Load

-

26 T

26 TOperating Weight

-

30000 kg

30000 kgLifting Capacity (kg)

- about

- Technical Innovation

The Casagrande hydraulic crawler cranes offer a practical solution for a large range of applications from lifting operations to diaphragm walls or bored piling.

The machines are of robust design in order to withstand the rigors of site. They mount heavy duty winches with controlled or free fall mode of operation.

The controls and hydraulic system are versatile, designed to drive casing oscillators, rotary drills, vibrators and diaphragm walls grab.

The control system will help the operator maximize on performance and minimize on down-time.

Casagrande offers a range of hydraulic crawler cranes designed by a foundation equipment manufacturer and tailored to the needs of the piling contractor.

Technical Data

| Hydraulic Crawler Canes | EU | USA |

| Lifting capacity | 40 t | 3,9 m | 88,200 lbs | 13 ft |

| Engine power | 227 kW | 304 HP |

| Main winch | 240 kN | 54,000 lbf |

| Auxiliary winch | 83 kN | 18,700 lbf |

| Max boom length | 30 m | 98 ft |

| Operating weight | 44 t | 97,000 lbs |